Services

Teddington Engineered Solutions offers a wide range of services connected to the design, manufacture, maintenance and repair of high-quality metal, rubber, fabric and PTFE bellows expansion joints. All such services are conducted either in-house or on-site, making Teddington a one-stop solution and giving us more control over critical processes.

Our FastTrack service delivers rapid manufacturing and expedited delivery of expansion joints, metal bellows and flexible connectors. Ideal for urgent pipeline and process system projects, this priority production option ensures short lead times without compromising quality, precision or performance. Get reliable, fast-turnaround expansion joint solutions to meet tight project schedules and minimise costly downtime.

We offer custom engineering and bespoke design for bellows and expansion joints tailored to your unique specifications. Our team provides advanced design, materials expertise and precision fabrication for demanding environments. From simple to complex, vacuum to high-pressure, cryogenic to high-temperature, small diameter or very large (>12m), thin multi-ply or thick-wall, we deliver engineered-to-order expansion joint solutions optimized for safety, durability and performance.

Explore our catalogue of standard expansion joints, metal bellows and flexible connectors, designed for compatibility with most industrial and commercial piping systems. Available in a wide range of sizes, materials and configurations, our stock products ensure cost-effective, rapid deployment while maintaining durability, reliability and performance. All expansion joints are manufactured to international quality standards.

Our Finite Element Analysis (FEA) service delivers precise simulation of bellows and expansion joints. Using advanced software, we analyse stress, thermal load, vibration and fatigue conditions to verify strength, durability and performance. FEA ensures code compliance, optimal design and failure prevention for high-pressure, high-temperature and movement-critical piping systems.

We can provide guidance on pipeline layout, advising the most efficient and cost-effective design and placement of expansion joints, metal bellows and flexible connectors. Our engineering team evaluates system flexibility, anchor placement, thermal movement and pressure loads. The result is an optimized layout that reduces stress, prevents fatigue and extends the operational life of critical piping systems in demanding industrial environments.

We offer expert on-site installation guidance for bellows, expansion joints and piping systems, verifying alignment, pre-setting, anchoring and bolting to ensure correct fitment and prevent premature failure. Our on-site inspection and NDT service allows our engineers to identify root causes of fatigue, leaks and misalignment issues and deliver corrective action plans or replacement parts.

Our certified welding services support the fabrication and repair of expansion joints, bellows and associated pressure components, as well as pipework and pressure vessels. We specialize in TIG, MIG and ARC welding for carbon steel, stainless steel and other exotic alloys. All welding is performed to the most relevant industry standards required to ensure structural integrity, leak-tight performance and long-term durability in high-pressure and high-temperature environments.

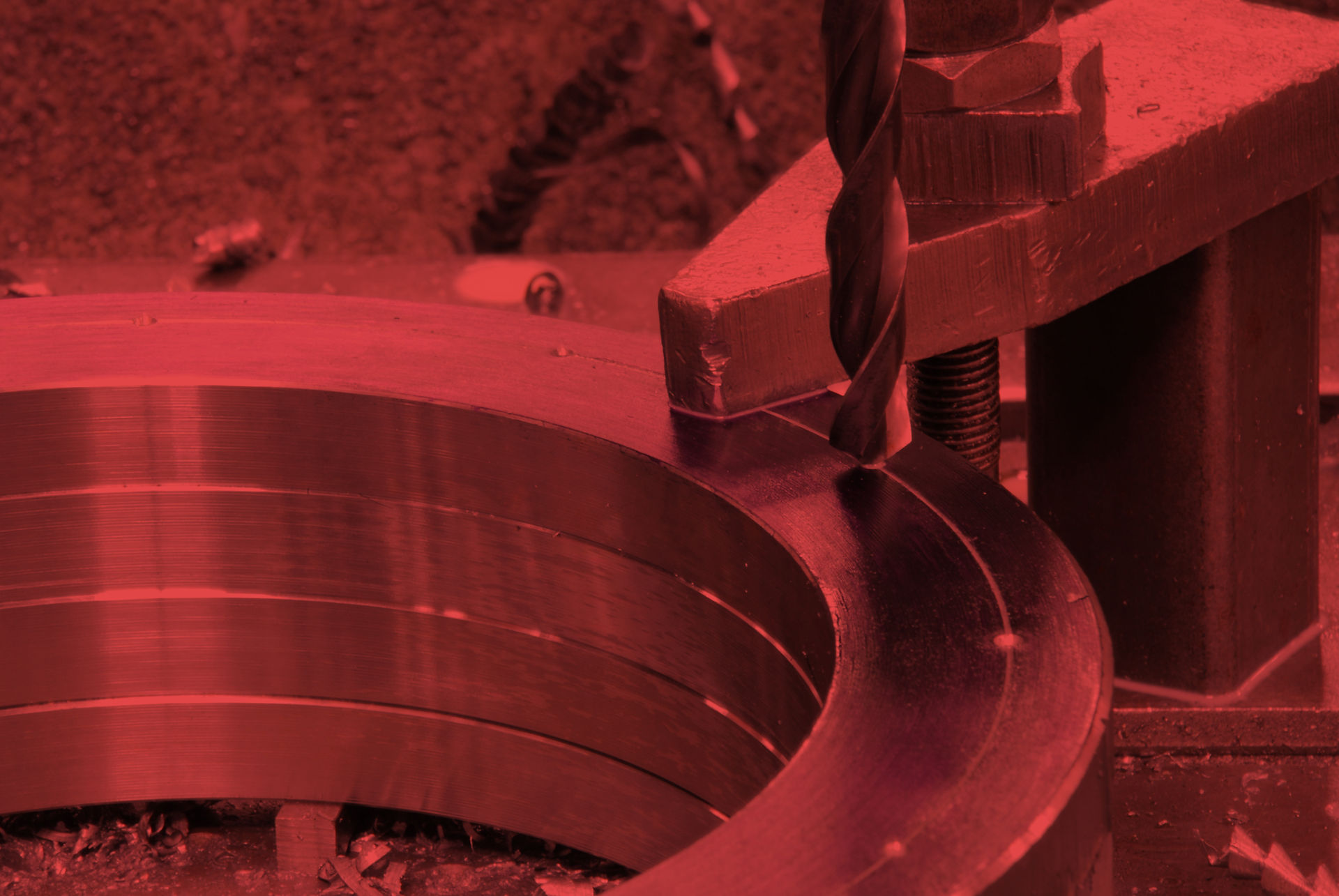

Our advanced CNC machining capabilities enable precision manufacturing of components for a wide range of applications as well as for our own use on bellows. We produce custom flanges, end fittings, collars and support hardware with tight tolerances using stainless steel, carbon steel and alloys. CNC machining ensures consistency, repeatability and rapid turnaround for both one-off and high-volume production.

We offer expert salvage, repair and refurbishment services for damaged or worn bellows and expansion joints. Our team restores critical components through painting, grit-blasting, re-welding, part replacement and re-testing to extend service life and minimise downtime. Ideal for cost-effective maintenance, our refurbishment services restore original performance to ensure system reliability and compliance.

We provide industrial-grade painting and coating services for expansion joints, bellows and fabricated steel components. Our coatings include epoxy, polyurethane, zinc-rich primers and high-temperature resistant finishes, offering long-term protection from corrosion, chemicals and UV exposure. Applied in controlled environments, our coatings enhance durability, aesthetics and compliance with industry specifications.

Our grit-blasting services clean and prepare metal surfaces prior to coating or inspection. This abrasive cleaning method removes rust, scale, old coatings and contaminants, ensuring a high-adhesion profile for paint and coatings. Grit-blasting enhances surface integrity, corrosion resistance and overall durability for long-term performance in harsh environments.

We provide a range of non-destructive testing (NDT) services, including X-ray testing (radiographic inspection), Ultrasonic testing and dye-penetrant testing to detect internal defects and discontinuities. These non-destructive testing methods ensures weld quality, material integrity and compliance with required industry standards. X-ray inspection in particular is critical for pressure-containing components where internal flaws could compromise safety or performance in service.

We perform hydraulic, hydrostatic and pneumatic non-destructive testing (NDT) on bellows to verify strength and leak-tight integrity. Helium leak testing uses mass spectrometry to detect microscopic leaks in expansion joints that traditional methods may miss, ensuring gas-tight performance. All pressure tests are conducted in-house to client specifications and international standards, ensuring safe performance under operating conditions and structural integrity of all critical components.

We conduct fatigue or life-cycle testing on bellows to assess durability under cyclic load conditions. By simulating pressure fluctuations, movement and thermal cycling, we verify design life and failure thresholds. Fatigue testing has been conducted under cryogenic conditions down to -168ᵒC and high-temperature conditions up to +1400ᵒC. Fatigue testing ensures long-term reliability, safety and performance in applications where repetitive stress may lead to material fatigue or failure.

In addition to Fatigue Testing, we conduct Squirm and Burst Testing under pressure and temperature-controlled conditions. Squirm Testing is a destructive test which identifies the pressure point at which bellows lose structure due to instability by simulating internal pressure conditions. Burst Testing determines the maximum pressure capacity of expansion joints by applying internal pressure until failure, confirming whether it conforms to the relevant safety margins and industry standards.

.png)